Fun With Recon!

The term 'recon' is short for reconstituted stone. It is a fabricated material that is often harder than the original stone it is derived from. For example, most native turquoise is very soft, some chalky, which means it needs to be stabilized before it can be cut and polished effectively. One form of stabilization is to pulverize it into powder or small bits, then mix it with various resins and epoxies, finally pressing it into blocks under extreme pressure.

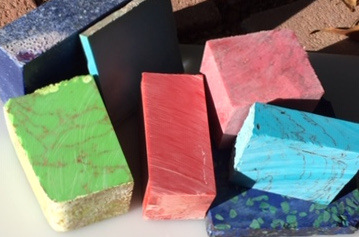

The percentage of actual stone contained within each block varies by several factors. As you can see in the picture, those are some bright colors usually not found in natural rock. Dyes are often mixed in with the recon 'soup' to provide the vibrant colors. The actual content of stone within any block of recon is between 0% and 75% stone. That's right, some recon actually contains no natural stone, but provides striking hues where such colors might not be found in nature. In addition to stone and various resins, other inclusions to the mix create patterns that resemble healed fractures that might appear in the natural stone.

Working with recon as a lapidary material is not much different from a natural stone with a mohs hardness of around 5. It can be cut on a diamond saw blade, and ground with diamond or silicon carbide wheels. Polishing can be done traditionally with finer grade sanding with resin belts, but I have found that I can take a 600 grit sanded piece straight to a muslin buff with Zam compound for a very high polish.

Recon is often used for inlay and channel work where striking colors compensate for very small areas, as there is a wide spectrum of colors available in recon. Also, recon is much cheaper than rare and often expensive natural material.

Another use for recon is intarsia. It is very easy to cut various shapes of recon and glue them together to make fun pieces. I have also made some intarsia mixing recon with natural stone, although it can be challenging to dodge the undercut of varying hardnesses.

I have made several jigs for my trim saw and grinding wheel that help produce the flush-facing angles that make the finished cabs look seamless. Lack of imagination is about the only limitation to what you can do with recon.

A little history...

The process for making the best recon was perfected right here in the United States where it was subsequently exported to asia for use in mass produced costume jewelry. Around the turn of the century, those same asian consumers figured out their own method of manufacturing recon. Consequently, the demand for US recon evaporated, even though the quality of the material made in asia is inferior to the US method. This left the leading US manufacturer of recon with a sizable inventory, is no longer producing it, nor actively marketing it.

If you are interested in purchasing any recon, drop me a message and let me know what you are looking for. I can either broker a purchase for you, or put you in contact with the owner for a wholesale deal.